研究案例:

The next figure shows the magnitude of the surface dilatational modulus for the C12-DMP at a concentration of 4.0x10-3 mol/l just below the cmc. The magnitude of the module increases at higher frequencies in a linear fashion. This feature is typical for a surface visco-elastic layer. The corresponding phase measurements yield a large phase-shift between piezo and pressure response at higher frequencies, a feature which clearly indicates for a surface viscosity.

The picture changes completely at lower bulk concentration of the very same surfactant. The corresponding measurements are also illustrated in the figure. The magnitude of the E-module levels off in a plateau at higher frequencies as predicted by the Lucassen - van den Temple model. The corresponding phase vanishes at higher frequencies.

The BubbleDrop Analyzer Optrel GbR measures a fundamental system parameter, the complex surface dilatational modulus. This parameter is decisive in the context of foaming but also for other technological processes such as in the new field of microfluidics where smaller volumes are manipulated or classical high speed coating processes in the photographics industry. The system has the potential to establish a new standard technique in colloidal laboratories.

Foam stability

What determines the stability of foams?

Surfactants enable phenomena such as foams. Foams can only be formed if surface active materials are present. A foam lamella consists of a thin water slab stabilized by two amphiphilic adsorption layers. Hence, it is tempting to search for correlations between the properties of the adsorption layer and the foam. This approach is in particular promising for wet foam lamellae where both adsorption layers are separated by a fairly thick water slab. Different rules may apply for Newton black films, where the adsorption layers are so close that their interaction governs the system behavior.

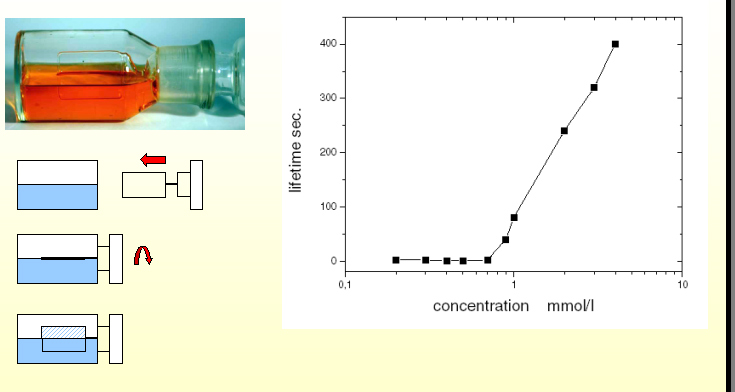

The surface dilational elasticity module E of a soluble cationic surfactant at the air-water interface is measured in a frequency range of 1 Hz to 500 Hz. The data are then correlated with the lifetime of a foam lamella formed with the same surfactant solution. The surface rheological measurement have been performed with an improved design of the oscillating bubble technique that measures precisely the real and imaginary part of the complex dilational module E. The imaginary part captures a dissipative process which is interpreted as an intrinsic surface dilational viscosity κ. The cationic surfactant 1-dodecyl--4-dimethyl-amino-pyridinium bromide shows a transition between a surface elastic to a visco-elastic behavior with an increase of the bulk concentration. The transition corresponds to a striking increase in the lifetime of the foam lamella. The lamella lifetime of the visco-elastic system exceeds the one of an elastic system by two orders of magnitude while the absolut value of the E-module remains comparable. The results suggest that surface dilational viscosity κ is crucial for the ability of a surfactant system to form a stable foam.

The intrinsic surface dilatational viscosity is decisive for the formation of stable foam lamella. Only solutions with a nonvanishing phase shift at higher frequencies form stable foam lamellae!

Further reading:

P. Koelsch, H. Motschmann, "Relating foam stability and surface dilational rheology" Langmuir (2005) in press |